Overview

This product is widely used in thermal power generation, metallurgy, ceramics, machinery, oil and mining, chemical industry, urban water supply, plastics, cement, papermaking, pharmaceuticals and other fields. It can realize speed regulation, energy saving, and control of various loads driven by various low-voltage motors. Soft start and intelligent control, the comprehensive benefits are very significant. Zhufeng Electric's DLT series low-voltage power savers and inverters with independent intellectual property rights have passed strict testing by authoritative departments such as the National Electric Power Research Institute and the National Electronic Control and Distribution Equipment Quality Supervision and Inspection Center in March 2004. In terms of quality assurance system, it has passed ISO9001-2000 certification. The company has been committed to energy saving and consumption reduction in the ceramic industry. The company's new product, ball mill power saver, has been highly praised by customers since its launch more than a year ago. It has significant power saving, stable operation, easy-to-understand operation, green and environmental protection, and greatly reduces mechanical wear and maintenance costs. Since the "Energy Conservation Law of the People's Republic of China" in 1997 pointed out the "strategic policy of energy conservation and consumption reduction", "energy conservation and environmental protection" have become the top priority of the government's work. At the same time, enterprises have also vigorously promoted "energy conservation and consumption reduction" . Reduce production costs and improve the competitiveness of enterprises. Therefore, our company is willing to cooperate with your company and make progress together!

Product introduction of ACI ball mill energy saver

ACI ball mill energy saver, energy saving rate is between 10% and 35%.

ACI plunger pump energy saver, energy saving rate is between 20% and 60%.

ACI mixer energy saver, energy saving rate is between 15% and 50%.

ACI fan dedicated energy saver, energy saving rate is between 20% and 70%.

ACI air compressor energy saver, energy saving rate is between 15% and 60%.

ACI kiln drive inverter, can effectively adjust and track speed.

ACI conveyor belt inverter, can implement speed control.

Ball mill energy saving principle

Wet ball mill (ceramic enterprise) is selected and configured according to the drum diameter, process requirements and production volume. It includes motor (prime power) reducer, hydraulic coupling, auxiliary motor, brake coil, pulley, drum, etc.

The original control was to run at a constant speed, and only through experience and experiments could we determine how much time it would take to make a product. That is, when the ball was running, the starting force distance was large and it was difficult to start. After a lot of experiments and data summaries by our company, we developed the ACI ball mill energy saver for the ball mill and produced a series of products DLT-QM11 control cabinets and Q11 controllers in various power ranges.

Working process: The ball mill is based on the movement of the medium, and the grinding process of the material particles occurs between the medium and the medium and between the medium and the liner. The medium movement is divided into the throwing type (suitable for coarse grinding), the falling type (suitable for fine grinding), and the centrifugal type (losing the grinding effect).

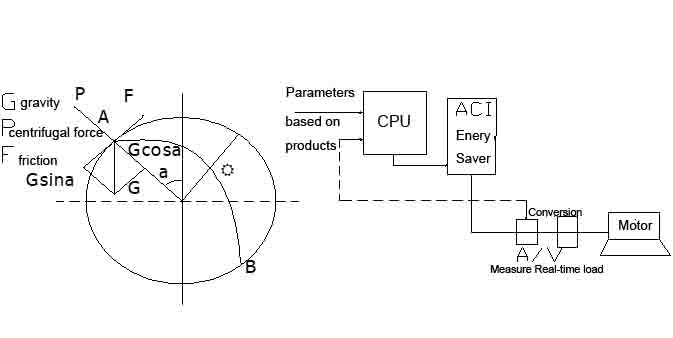

According to the above three movement modes and force conditions, in order to improve the ball milling efficiency, the ball mill energy saver adopts vector control calculation, decomposes the force longitudinally and transversely, makes it a scalar in the rotating shaft and controls it, and uses fuzzy theory to track and sample the ball mill, thereby adjusting the output torque and speed. It uses the most economical electricity to achieve the best grinding effect. As shown in the following figure:

Save electricity in four ways

Save electricity in four ways

The soft start function of the power saver can reduce the starting current by 4-7 times.

The power factor of the power saver can reach above 0.99, while the power factor of the original motor is below 0.88.

Because different products require different speeds, and because power is proportional to the square of the speed, we can set different control speeds at different time periods, and customers can freely set or choose (implemented through a microcomputer processor).

The power saver can automatically track the optimal operating current of the motor in real time, thereby adjusting the corresponding output voltage and torque to achieve the best economic operating point.

Based on the above four points, the comprehensive power saving effect can reach more than 10%-35%, with an average of about 15%, and the effect is very significant.

It is different from general frequency converters, soft starters, and power factor compensators. It is an organic combination of the three. It is a perfect combination of overcoming starting difficulties and effective energy saving. It is the energy-saving product preferred by modern ceramic enterprises.

Functions and characteristics of ball mill power saver:

ACI ball mill special power saver has a unique dynamic power saving function, with a power saving rate of 10% to 35%.

After installing the ACI ball mill special power saver, the ball mill starts up into a true soft start. The starting impact force of the ball mill is greatly reduced, and the service life of the ball mill's belt and gear is greatly improved.

After using this machine, since the starting impulse current and working current of the ball mill are both reduced, it will not cause grid voltage fluctuations and grid voltage reductions, and eliminate other faults such as tripping of other electrical equipment caused by this.

ACI ball mill special power saver has complete protection functions such as overload, overcurrent, short circuit and grounding.

The ball grinding time and automatic shutdown time can be conveniently set, and additional grinding time can also be conveniently selected.

Low investment and high return, all investments can be recovered within 5-12 months through savings in electricity bills.

The ACI ball mill special power saver produced by our company is specially developed and produced for ball mills through special improvements and software upgrades based on frequency conversion. It is different from ordinary general-purpose frequency converters. After the ceramic factory installed the ACI ball mill professional power saver, it is easy to start the ball mill, and the starting current can be controlled below the rated current (for example: 100-ton ball does not exceed 500A, 60-ton ball does not exceed 400A, 40-ton ball mill starting current does not exceed 300A) , so the starting performance of the equipment is very excellent, which greatly reduces the starting current of the ball mill, the impact on the power grid and mechanical equipment. It also improves the transformer capacity utilization efficiency by more than 20%. With the same transformer capacity, the number of multi-opening ball mills and equipment can be increased without the need to increase the capacity of the transformer, saving a lot of costs. In addition, it can also increase the service life of the ball mill belts, bearings, and reducer gears. etc. to save maintenance costs.

It will not cause grid fluctuations and grid voltage reduction when starting, eliminating the tripping and undervoltage faults of other electrical equipment caused by this. It is especially suitable for use in generators and ball mills where the power grid is low.

Necessity of energy-saving transformation of ball mill

Factories using ball mill equipment generally work long hours and consume a lot of electricity. The annual electricity bill reaches millions, which imposes a heavy cost burden on the factory. The electricity consumption of the ball mill accounts for 40-60% of the total electricity consumption of the workshop. Therefore, in order to effectively reduce costs, the problem of the ball mill's electricity consumption must first be solved.

The existing ball mill equipment and its working methods mainly have the following problems:

The current starting method and control method of the ball mill are not energy-saving. If modified, a large amount of electricity bills can be saved;

When the ball mill is started using the existing starting method, the impact force it receives is extremely large, which can easily cause damage to the ball mill bearings and gearbox gears, resulting in high maintenance costs;

When starting the ball mill using the existing starting method, the impact current is very large (usually 7-8 times the rated current), which will cause fluctuations in the grid voltage and reduce the grid voltage, causing other electrical equipment to trip and malfunction, which will inevitably affect normal production.

Therefore, it is extremely necessary to carry out energy-saving transformation for ball mill equipment. After the transformation, not only can electricity costs, maintenance costs, and cost expenses be significantly reduced, but by reducing line losses and line heating, the service life of the ball mill can be extended, noise pollution can be reduced, and the efficiency of the workshop's production power lines can be improved. Safety factor.

Contact: James

Phone: 18675899791

Tel: +86-18675899791

Email: info@ctitronix.cn

Add: Room 312, Yunfeng Commercial Building, No.2 Jinghu Road, Huadu District, Guangzhou 510800, China